From the depths of the ocean to the peaks of the Himalayas, the massive accumulation of plastics and their almost ubiquitous presence in any environment is one of the greatest environmental challenges threatening the planet. Recycling them under current conditions, far from being a definitive solution, is only a stopgap measure. The data are overwhelming: barely 9% of the millions of tonnes of plastics discarded annually around the world are recycled.

Some 12% is burned (generating greenhouse gases and other polluting emissions) and the remaining 79% accumulates in landfills or ends up in the sea. Moreover, in practice, only two types of plastics (PET and HDPE) are recycled on a large scale. And replacing them with other biodegradable materials is not a viable alternative either, given how easy and cheap they are to produce and how versatile they are. Against this backdrop, chemists are working to develop new and more effective ways of recycling.

Alternatives for handling mixed plastics

One of the main limitations of plastic recycling today is the need to process different types of plastic separately, as each has its own specific properties and requires specific treatment conditions, which in many cases are incompatible with each other. If they are processed in combination, the resulting product is defective. This is a limitation which, in addition, clashes with the fact that most packaging is made by combining plastics with different properties; their separation is, at best, difficult and costly.

Extraction or fractionation involves processing the mixture of plastics in successive stages using in each of them specific solvents for each material, so that in each “wash” or stage only one specific plastic is dissolved, which is separated from the mixture and recovered with a high degree of purity, ready to be reused. Although this technique has demonstrated its potential in the laboratory, it is not yet efficient or cost-effective enough for practical application and there is still a long way to go to achieve this goal.

The new compatibiliser additives take the opposite approach, enabling different plastics to be recycled together. These compatibilisers are designed with a molecular structure that allows polymers with different characteristics to bond with one another. One way of looking at this is to use the analogy of construction sets: imagine a mixture of two plastics, one consisting of Lego pieces and the other of Megablock pieces, which are incompatible with each other. These additives would act as connectors that fit the Lego pieces on one side and the Megablock pieces on the other, so that all of them could be played with at the same time. The use of compatibilisers is already a reality today, but the current ones are far from being efficient and cost-effective as it is necessary to add a significant amount of them to the mix. However, the new compatibilisers that researchers are working on have proven to be much more effective and powerful in the laboratory.

Minimising the degradation of plastics during recycling

The other big problem with current recycling is its limited usefulness, due to the presence of residual impurities (additives and dyes present in the original plastics), but above all because of the degradation that the polymers undergo during processing. In this process, the plastic mixture is melted and remoulded under very high temperature and pressure conditions that weaken or break the bonds within the polymers, which alters and reduces their strength and consistency. The result is a material of much lower quality than the original. The progressive deterioration with each cycle results in a very low reusability.

To overcome this limitation, new, gentler forms of recycling are being investigated, such as processing the plastics with nanoparticles of metal catalysts. These nanoparticles weaken the original long polymeric chains at specific points (bonds), allowing them to be broken down into smaller molecules or polymers under much more moderate conditions.

A comprehensive rethinking: chemical recycling

New techniques are also being investigated based on a comprehensive rethinking of the recycling process. Returning to the Lego analogy, the original shapes would be disassembled into various parts with heterogeneous shapes and made up of blocks of different sizes, shapes and colours. The new treatments aim to completely dismantle the figures to be recycled into their individual pieces so that they can then be reassembled as desired and a new structure can be built as if it were the first time. Chemical recycling involves using molecules specifically designed to act as molecular scissors to cut the polymer chains at specific bonds, releasing smaller units that can be re-combined to produce new plastics. Like most of the new recycling methods presented, this is a technique that has so far proved effective in the laboratory but is still too costly for large-scale application in the short term.

A variant of this chemical recycling that is now almost a reality is biochemical or enzymatic recycling, in which instead of molecules designed from scratch, enzymes from micro-organisms are used to break the bonds of plastics. The French company Carbios is building a recycling plant in France that is expected to be operational by the end of the year to operate on an industrial scale the biochemical recycling system based on a microbial enzyme, cutinase, which breaks down PET plastic into its constituent monomers.

A new generation of plastics to the rescue: PDKs

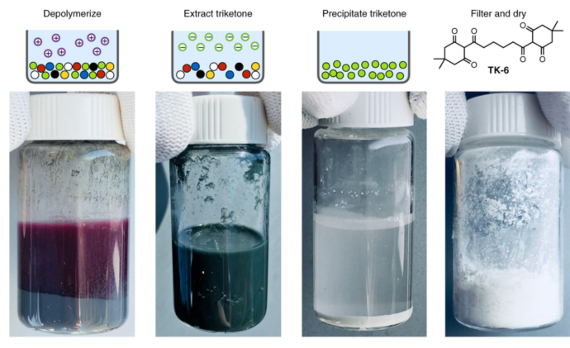

But perhaps the ultimate revolution to come is the promise of a new generation of plastics specifically designed to be recycled and reused continuously: poly(diketoenamine)s, or PDKs, which have the ability to break down into their starting monomers under ideal specific conditions (e.g. when treated in a sufficiently acidic environment) and without deterioration; they can then be reassembled into a new plastic, time and time again.

These reversible polymerisation plastics ensure the recovery of the monomers free of impurities even in waste mixtures. In addition, the starting monomers are highly versatile assembly units designed to be combined in a variety of ways to produce plastics with different properties and applications. The aim now is to optimise both their capacities and their production in order to deploy them on a large scale and thus minimise the environmental impact.

Comments on this publication