Last February, a study published in the journal Science estimated that in 2010 between 4.8 and 12.7 million tons of plastic rubbish were dumped in the world’s oceans. Although this is a frightening number, it is only a small part of the 275 million tons that were generated that year in 192 coastal countries. World production of plastics has increased some 500% since 1980, and these materials represent between 80% and 90% of maritime pollution. However, most of it stays on land, and it is in developing countries with poorer sanitation and recycling systems where the problem of plastic pollution is of particular importance. In fact, developing and emerging countries are mainly responsible for plastic pollution; according to the study in Science, of the 20 most polluting countries only the twentieth is a western developed nation, the United States.

Is it possible to conceive of a future without plastic? Some predict that the future depletion of fossil fuels will force it and that it will be necessary to develop substitutes. But even if this comes about, the end of plastics would not mean their disappearance from the Earth due to the very slow degradation of these polymers, and thus it will be necessary to also address means of decontamination. This is the background for the efforts toward the goal of achieving a world without plastic.

Living without plastic

Some media campaigns and blogs, such as MyPlasticFreeLife.com or LifeWithoutPlastic.com, or books such as Living Without Plastic by Brigette Allen and Christine Wong (Artisan, 2020), offer hints and tips on how to minimize the consumption of these materials and keep track of one’s personal plastic footprint. Attempts to live without plastic are based mainly on choosing purchase options that are limited to the use of traditional materials such as glass, paper, metal, ceramic or stone and buy food in bulk rather than packaged.

But it is not easy; synthetic resins are present, one way or another, in most of what we buy, consume and discard. The reason for this is that oil polymers allow for great flexibility and diverse properties, and making the reverse journey toward materials of natural origin does not seem to be a universal solution. Monitoring and reducing the use of plastic is the mission of organizations like Plastic Disclosure Project. The latter bases its objectives on its motto of the four Rs: refuse, reduce, reuse and recycle.

Ban plastic?

Beyond the personal or non-governmental initiatives, authorities in many countries have decided to take legal measures to cut the consumption of plastics. In 1990, the island of Nantucket became the first place in the US to ban single-use bags. Other cities and counties then followed suit. Bangladesh was the first country to introduce such a ban in 2002, and in August 2014 California became the first US state to pass similar legislation. In China, the decision to charge consumers for disposable bags, introduced in 2008, succeeded in reducing the amount of disposable plastic bags by 50%; the country is now in the process of phasing them out. Some developing countries have outlawed plastic bags, although enforcement of these measures is sometimes problematic. At least 90 countries have already imposed bans on single-use plastics, and a total of 170 countries have committed to significantly reduce the use of plastic by 2030.

The European Union has not yet implemented a general prohibition, but has agreed to impose on member states the obligation to reduce by 80% the use of the lightest bags over the next decade –shifting from over 170 bags used each European per year to just 40 in 2025– or heavily tax their use from 2018. Some countries surpassed this: Italy was a pioneer in eliminating non-biodegradable bags in 2011, while France banned single-use bags in 2016. From July 2021, the EU will phase out certain single-use plastics, such as cutlery, plates, cups, food packaging, swabs, drinking straws and balloon sticks.

Biodegradable plastics and bioplastics

The first step in attempting to reduce the plastic footprint of the human being is producing biodegradable polymers by using additives. However, this does not solve the problem of its petrochemical origin, which still involves the use of a non-renewable resource. Therefore, the next step is to obtain substitutes that do not depend on oil.

Steady progress is being made in the manufacture of bioplastics based on materials such as starch or cellulose. An example is polylactic acid, a bioplastic similar to polystyrene produced from the same compound that causes tooth decay. But it should be noted that not all bioplastics are biodegradable. Polyethylene, the plastic of bags, has a biological version obtained from the fermentation of cultures, but just like the plastic derived from petroleum, it is not biodegradable.

Among new plastics from a biological source and with easy biodegradation, scientists work on the production of plastics from edible vegetable waste, such as parsley, spinach stems and the husks from rice or cocoa pods. The advantage of the method is that it allows for a wide range of cellulose bioplastics, from the most rigid to the soft and bendable.

Nevertheless, many experts warn that bioplastics are not a panacea: the production of single-use materials is still resource-, water- and land-intensive, and the degradation of these materials is not as simple or immediate as one might think, with much of it ending up in landfill or the oceans. The desirable thing, they insist, is to change our habits and abandon the practice of using disposable materials.

Microbes and caterpillar that eat plastic

Even in an ideal situation, with petrochemical plastics limited to uses where there is no other option and always in long-lasting applications; with all disposable uses reduced to a minimum and covered by biodegradable bioplastics; and with extensive recycling…. even then there would still be millions of tonnes of plastic waste to dispose of. Of particular concern is how these materials break into fragments over time to produce microplastics that contaminate virtually all terrestrial habitats.

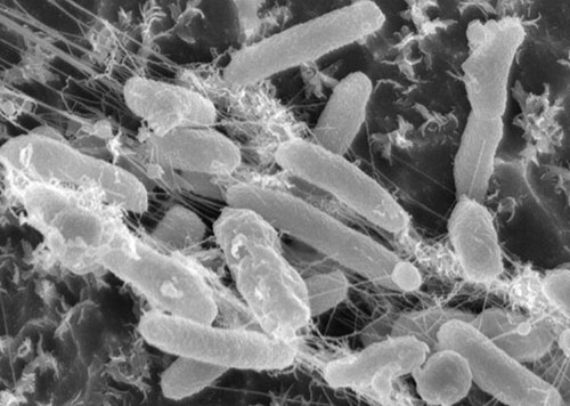

What to do with this plastic waste? Almost all eyes are on biotechnology, the use of microorganisms capable of degrading plastics. There are bacteria, such as the soil microbes of the genus Pseudomonas, and even fungi like those that grow on wood, that can digest plastics naturally. The downside is that the biodegradation of plastics in this way usually requires special conditions, such as high temperatures or ultraviolet light.

New plastic-degrading microbes have been discovered in recent years: in a bottle recycling plant, Japanese scientists found a bacterium they named Ideonella sakaiensis that consumes PET, the most common material in these containers. In the Mediterranean, Greek researchers have found natural microbes that consume polyethylene and polystyrene in marine waters with similar efficiency to other genetically modified ones. Elsewhere, a variety of plastic-eating microorganisms have also been found, and genetic engineering is advancing to enhance these natural microbial capabilities.

It’s not just microorganisms that can help us in the task of destroying plastic waste. In 2014, Chinese researchers observed that the caterpillar of a particular type of moth often feeds on food packaging. By examining its digestive tract, they found two kinds of bacteria that degrade polyethylene without the need for further treatment. Other scientists have described similar capabilities in other caterpillars. However, some experts question whether the use of organisms offers a practical and time-efficient solution to plastic pollution.

Chemical recycling

In developed countries, efforts are focused on increasing plastic recycling rates. However, experts warn that recycling is not necessarily a final solution: unlike glass packaging, plastics are not used to make similar containers, but very different objects that can end up in landfills. Even permanent uses, such as building roads with plastic waste, can also generate polluting microplastics.

A growing trend exploits an interesting alternative: since plastic is produced from oil, why not convert it back into fuel? Unlike the mechanical recycling we are already familiar with, which consists in separating types of plastic, grinding them and melting them down to create new products, so-called chemical recycling is based on breaking the long polymer chains into smaller units. The two most commonly used methods are gasification, which produces a gas from which diesel or paraffin can be obtained, and pyrolysis, which generates a mixture similar to crude oil. Current research is focused on optimising the processes to obtain the maximum amount of fuel while minimising resource consumption, energy requirements and cost. However, although this is an interesting option for the circular economy, the impact of these solutions in terms of their carbon footprint is still under discussion.

Bonus video: Garbage Island: An Ocean Full of Plastic (by VICE)

Comments on this publication