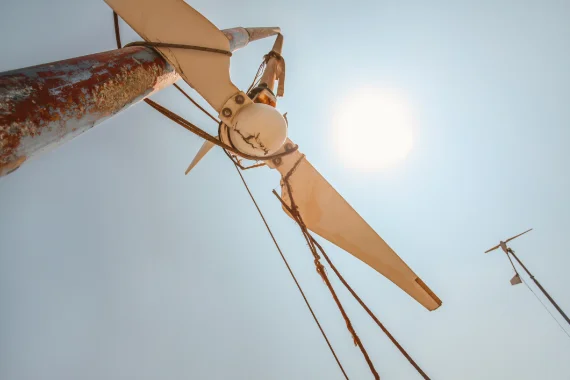

Solar photovoltaic panels and wind turbines deliver one treasure—clean energy—and promise another: precious metals, rare earths and recycled glass fibre, carbon fibre and value-added resins. Can this be done on an industrial scale?

By the end of this decade, waste from clean energy installations, mainly wind turbines and solar photovoltaic panels, will increase 30-fold in Europe, according to the European Environment Agency (EEA). This figure is intuitive, given the rapid growth in renewable energy generation over the past two decades and the fact that the useful life of wind turbine blades is between 15 and 20 years maximum and that photovoltaic panels between 25 and 30 years maximum. The current decade will therefore inevitably see a sharp increase in the amount of obsolete equipment.

A mindset focused solely on ecology would see an obvious environmental risk and a contradiction between the promise of clean energy and the polluting impact of its non-recycled infrastructure. “We cannot embrace renewables without closing the loop on sustainability, both in terms of the use of materials and techniques that are not sustainable,” says Fernando Ferrando, president of the Renewables Foundation, a think tank based in Spain. A business-oriented mindset, however, would identify an obvious business opportunity in a recycling industry that is currently still in its infancy, but whose demand is expected to grow as the volume of waste increases.

Both views would be correct. However, a more complex and realistic perspective, which recognises the need to reconcile environmental sustainability with economic sustainability (which ultimately provides the resources to finance the expensive energy transition), would see a business opportunity that still has to overcome huge investment, technological and even attitudinal challenges.

At the heart of decarbonisation and industrial sovereignty

The knowledge base is undoubtedly there, but whether this specialised industry will develop at the pace and scale that these predicted mountains of obsolete material will require is another matter. The EEA believes that in order to lead this new market, the European Union should push for “circular economy policies in this emerging sector at an early stage.” For some specialist companies, such as Recyclia, the advantage of such a large volume of material to be recycled is the economies of scale that will eventually make the huge investments required profitable.

In this context, a recent study by EIT InnoEnergy highlights the crucial role of the recycling industry not only in decarbonisation, but also in another priority that has emerged in the wake of the supply crises and the war in Ukraine: the industrial sovereignty of a Europe that imports 80% of its raw materials. It is also an opportunity in the form of a necessity: to recover 30% of the cobalt and 20% of the nickel and lithium in spent batteries to meet demand in 2035, as well as the rare earths in the electrical machinery of wind turbines and the silver in solar photovoltaic panels, barely 0.5% of their mass but no less than 47% of their economic value.

Looking at the big picture, the recycling industry appears to be in an advantageous position, as 80% to 90% of the total materials in wind and photovoltaics are easily recoverable, such as glass, metals like steel or aluminium, concrete and some plastics. However, a closer look reveals the difficulty, and therefore the barrier to industrialisation, in the remaining strategic percentage.

Technologies already exist to recover silver, silicon, copper, rare earths, or glass and carbon fibres mixed with resins in wind turbine blades, by far the most resistant component to recycling in wind turbines. The technologies are there, but they lack the development and investment support to reach a massive scale in the next few years, according to Alfonso Bernabé Chaves, founding partner of the company Reciclalia. If the deadline of this decade seems very tight, it will become even tighter when the European Commission bans the disposal of decommissioned wind turbine blades in landfills. In fact, the European wind power industry itself is calling for such a ban by 2025, in theory to encourage recycling. According to Bernabé Chaves, since some countries have already gone ahead and banned the disposal of turbine blades in their landfills, they are being trucked across borders. Decommissioned French turbine blades, for example, end up in Spanish landfills, particularly in the Basque Country.

The promise of industrial recycling

The technologies are therefore at different stages of development. Fernando Ferrando believes that the recycling of valuable metals from solar panels is already possible, although some processes, such as the removal of polymers, still need to be perfected in order to recover them with the high purity required for their reuse. Again, it remains to be seen whether this capacity will be scaled up to the required levels if, in addition to solar farms, domestic solar panel installations take off in Europe in response to skyrocketing electricity prices.

For its part, the turbine blade recycling industry is in a complicated situation, according to Bernabé Chaves, the driving force behind Reciclalia, a small Spanish company that has won the Retina Award for Sustainable Ecosystems and a runner-up prize from the French state-owned electricity company (EDF). Reciclalia has patented a system that is unprecedented in Europe and the USA—where it tops the list for its “industrial applicability”—to recover 100% of the glass fibres, carbon fibres and resins from turbine blades with a sufficient degree of purity to return them to a high value-added use. The technology exists, of course, but at present “it would not be possible to significantly increase the current capacity if we want to maintain a quality of recycled fibres that would allow us to do something very important: reuse them in the manufacture of new blades, in the automotive industry or in aeronautical applications,” says the expert.

So what is needed to give a real boost to the great promise of industrial recycling? In addition to investment that matches the need and the urgency, Bernabé Chaves points to a cultural change, especially among the boards of directors of some of the sector’s large companies, which he says are more obsessed with immediate profit and developing small recycling projects to attract subsidies than consolidating them un the lond term with a much greater scope. “Just think that by 2025 we will have up to 1.2 million tonnes of materials from wind turbine blades on European soil. If the decision-makers don’t change their mindset and pass it on to the management chain, this problem will never be solved,” says the entrepreneur.

The president of the Renewables Foundation has given a lot of thought to the profitability of the new industry, at least in its early years: “In most cases, renewable recycling will be an additional cost because the value of the recovered materials won’t cover the cost of carrying it out. But internalising and embracing the process is a must. To emphasise the current difficulties of recycling, when the process is still in its infancy, with positive results and in a phase of cost optimisation, or to emphasise the availability of the materials, is to put the focus on nothing changing or on this process being as slow as possible.”

Comments on this publication